Active Sludge Purifiers

Active Sludge Purifiers DSS100-1000

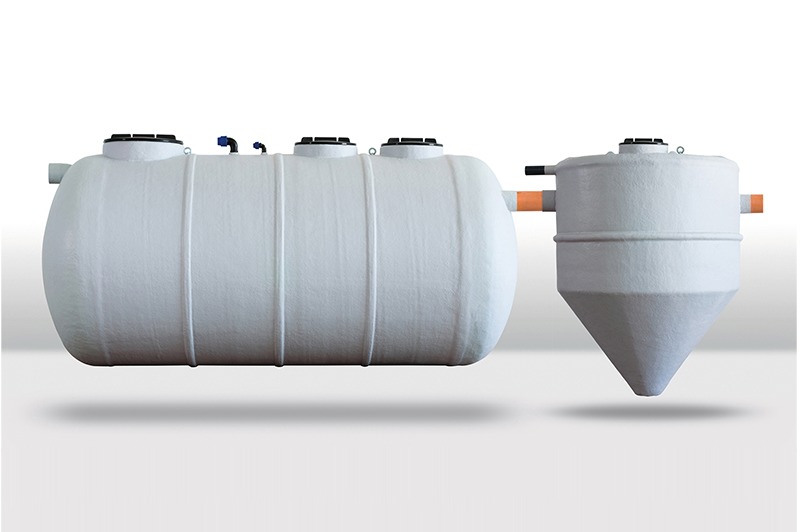

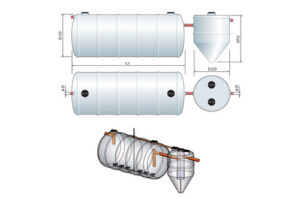

The Active Sludge DSS100-1000 purifiers made by Eco Depurazione entirely in GRP (Glass-Reinforced Polyester) are modular structures comprised of a monoboc horizontal cylindrical oxidation basin and a monobloc sedimenter sized for the primary treatment of waste waters coming from civil discharges or integrated waste characterised by a strong grade of mixed type organic substances based on the various uses for which the water is destined.

Operation

In the oxidation basin the organic substances are metabolised by action on the aerobic bacterial flora, favoured by an intense aeration via opportune fine bubble air diffusers connected with PVC piping to a side channel blower. The waste water coming from the oxidation section arrives at the sedimenter where the sludge flakes are separated from the water with opportune retention times in a settling zone.

The waste water coming from the oxidation section arrives at the sedimentation section where the sludge flakes are separated from the water with opportune retention times in a settling zone adjacent to the oxidation catchment area which it is in communication with via two opportunely interposed baffles.

In this phase the treated water is separated from the sludge which is partly recirculated into the oxidation section via an air-lift in order to maintain the aforementioned aerobic conditions. The clarified water in turn is conveyed to the disposal after passage into an opportune well which allows drawing for checks on the water required by law. The treatment allows for a strong decrease of the BOD5 which influences the sludge with significant mineralisation.

Item Specifications

Supply of an active sludge DSS100-1000 purification system made entirely from GRP (Glass-Reinforced Polyester) comprised of a monobloc horizontal cylindrical structure sub-divided into two different sections, for removal of the organic substances, and a monobloc sedimenter, for the separation of the sludge flakes from the water; complete with waste water intake and output gates, upper compartment inspection manholes, fine air bubble diffusers, side channel blowers and connection piping.

The system is sized to guarantee the limits established for civil waste waters in accordance with Legislative Decree No. 152/06 and subsequent modifications and integrations.

Dimensions

DEPURATORE A FANGHI ATTIVI IN VETRORESINA ART. DSS100-1000

Vasca di Ossidazione | Sedimentatore | Soffiante | |||||||||

ARTICOLO | AB/EQ | Dimensioni mm | Dimensioni mm | ||||||||

N. | Mc | ØD1 | L1 | N. | Mc | ØD2 | HT2 | N. | KW | ||

DSS100 | Max 100 | 1 | 15,00 | 2100 | 4950 | 1 | 5,00 | 1800 | 2850 | 1 | 3,00 |

DSS120 | Max 120 | 1 | 18,00 | 2500 | 4300 | 1 | 6,00 | 2100 | 3150 | 1 | 3,00 |

DSS150 | Max 150 | 1 | 22,50 | 2500 | 5300 | 1 | 7,50 | 1800 | 3800 | 1 | 3,00 |

DSS200 | Max 200 | 1 | 30,00 | 2500 | 6900 | 1 | 10,00 | 2500 | 3650 | 1 | 4,3 |

DSS250 | Max 250 | 1 | 37,50 | 2500 | 8550 | 1 | 12,50 | 2500 | 4150 | 1 | 4,3 |

DSS300 | Max 300 | 1 | 45,00 | 2500 | 10200 | 1 | 15,00 | 2500 | 4650 | 1 | 5,5 |

DSS400 | Max 400 | 2 | 30,00cad. | 2500 | 6900 | 2 | 10,00cad. | 2500 | 3650 | 1 | 7,50 |

DSS500 | Max 500 | 2 | 37,50cad. | 2500 | 8550 | 2 | 12,50cad. | 2500 | 4150 | 2 | 4,3 |

DSS600 | Max 600 | 2 | 45,00cad. | 2500 | 10200 | 2 | 15,00cad. | 2500 | 4650 | 2 | 5,5 |

DSS1000 | Max 1000 | 4 | 37,50cad. | 2500 | 8550 | 4 | 12,50cad. | 2500 | 4150 | 2 | 7,5 |

QUADRO ELETTRICO:

ARTICOLO | Descrizione |

EM/LTS3/AC24 | Quadro elettrico di comando per soffiante KW. 3.00 con usc.allarme 24V |

EM/LTS4/AC24 | Quadro elettrico di comando per soffiante KW. 4.00 con usc.allarme 24V |

EM/LTS5/AC24 | Quadro elettrico di comando per soffiante KW. 5.5 con usc.allarme 24V |

EM/LTS6/AC24 | Quadro elettrico di comando per soffiante KW. 7.5 con usc.allarme 24V |

Data sheet

Materials used

- GRP (Glass-Reinforced Polyester)

- STRUCTURE – PVC PIPING

- PP (Polypropylene) MANHOLES

Standards

D.LGS N.152/06 S.M.I.

further information?

Contact us for more information at the following addresses or fill out the form below:

- Tel. [+39] 06.92.58.722

- Fax. [+39] 06.92.58.722

- info@ecodepurazione.com

Eco Depurazione

Italian company specialized in the production of fiberglass products for applications in the sector of wastewater purification plants, for the storage and treatment of fluids in the civil and industrial sectors.

Products

- Purification

- Tanks

- Nautical

- Polyethylene products

Contacts

- Registered office: via Nairobi, 40 - 00144 Roma

- Operational Headquarters: Via Spaccasassi, 1 Aprilia (LT)

- Tel. [+39] 06.92.58.722

- Fax. [+39] 06.92.58.722

- info@ecodepurazione.com

- info@ecodepurazione.it

- P.IVA 02061210593

Cookie Policy | Privacy Policy | Gestione dati